Have cracks developed in the concrete floor of your business premises, or are you looking for a solution to waterproof the concrete and protect the structure? At SealteQ, we repair concrete using high-quality injection techniques. Below we explain what this achieves and how our specialists apply this innovative method.

Concrete Injection

Concrete injection techniques

1. Sealing concrete by injection (waterproofing)

Concrete injection is primarily used to make concrete watertight. Concrete is inherently porous, meaning it can absorb and allow water to pass. The resulting moisture issues can lead to structural damage, for example when reinforcing steel corrodes.

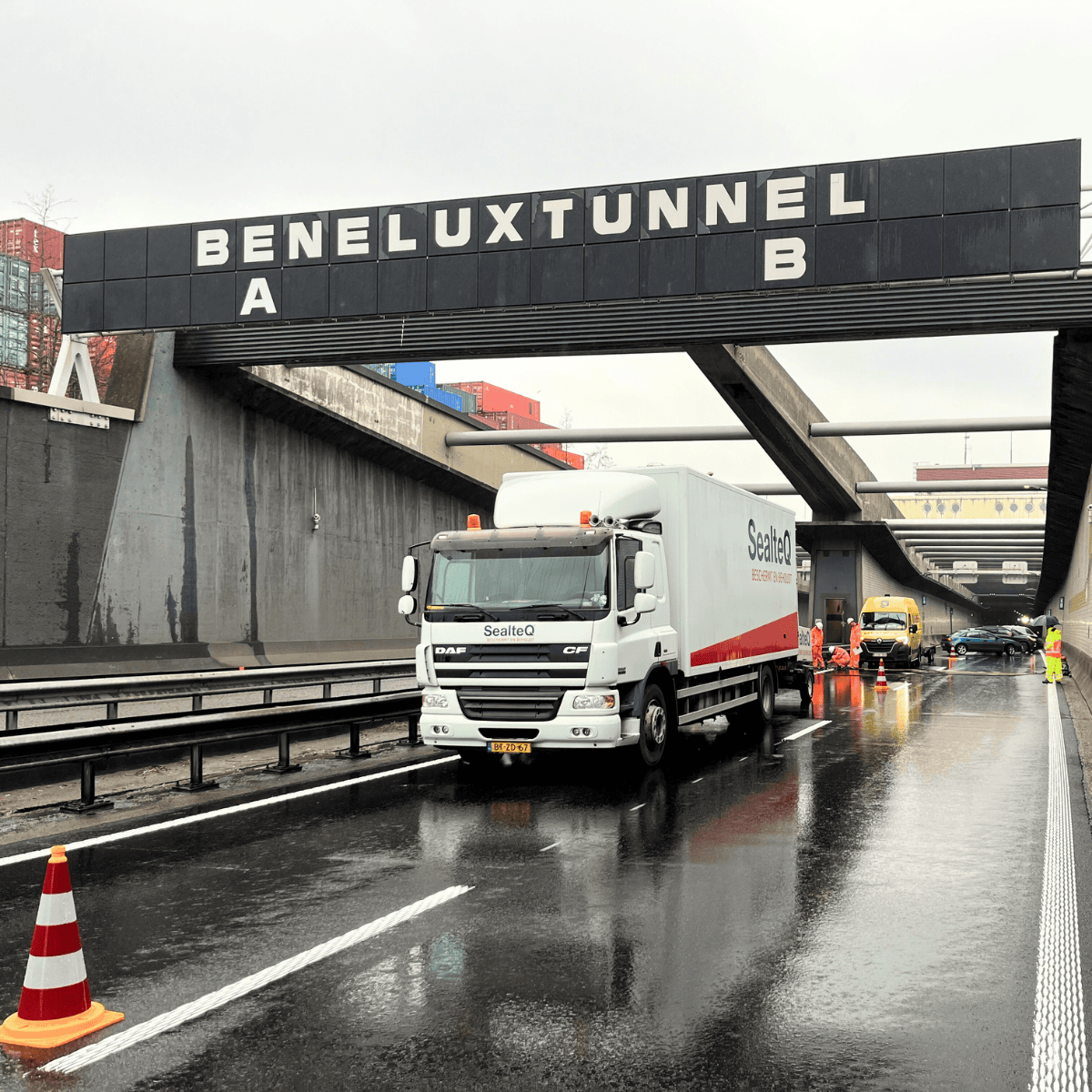

We prevent this by injecting the concrete with waterproof materials such as resins or hydrophobic chemicals. Watertightness increases, meaning the concrete no longer lets moisture through. The service life of concrete structures in, among others, basements, tunnels and parking garages is significantly extended.

Injecting Concrete Walls below the Groundwater Table

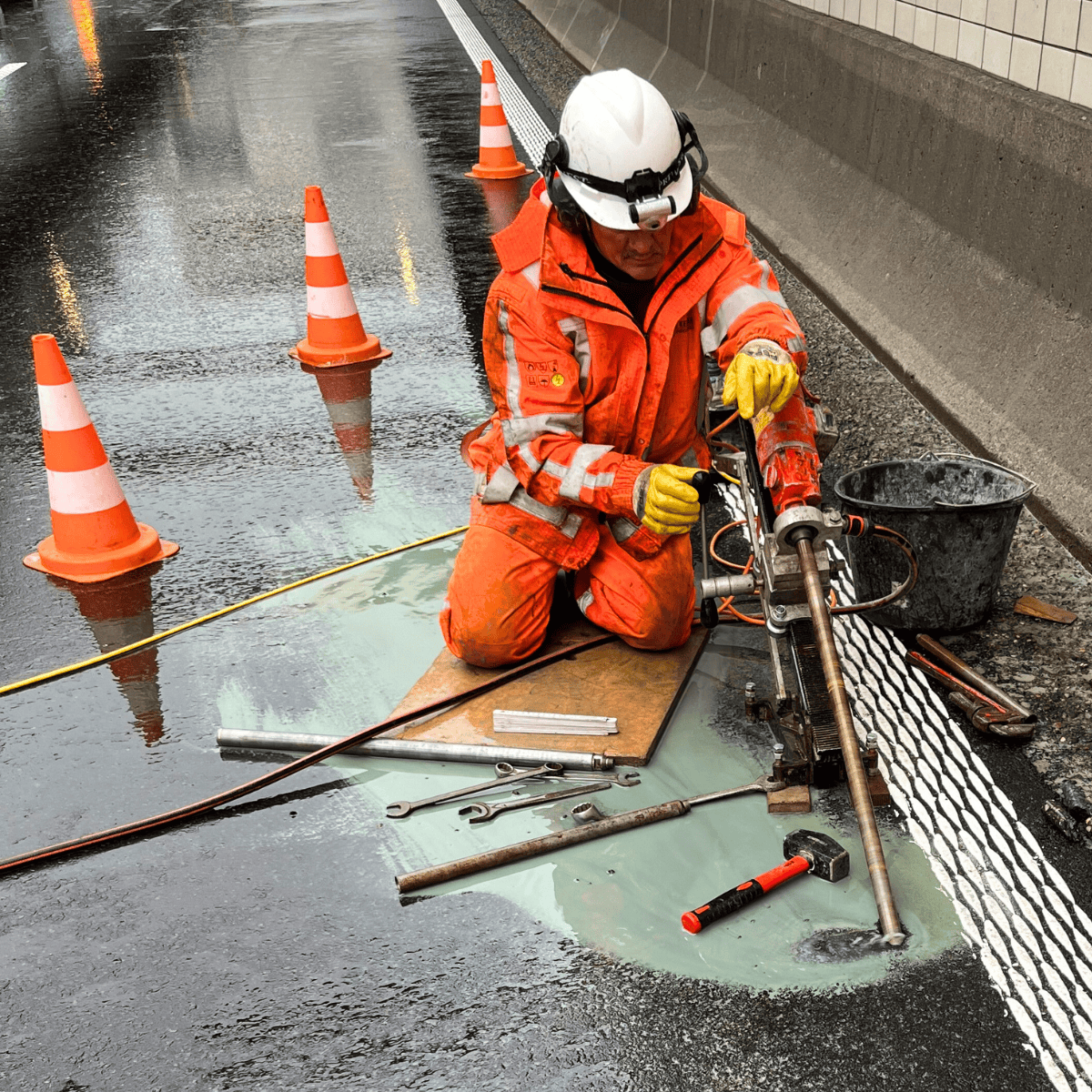

Concrete walls below the groundwater table require extra attention regarding moisture protection. In such damp environments, strong adhesion and resistance to groundwater pressure are essential. That is why, at SealteQ, we use concrete injection with the following materials:

- Polyacrylate is a gel injected behind concrete walls, where it forms a barrier. To ensure optimal watertightness, we tailor the gel to the specific structure and substrate.

- Polyurethane is used to repair cracks in concrete floors or to seal expansion joints that occur due to shrinkage and expansion.

2. Structural injection of concrete

Concrete injection is also used for structural purposes, enabling the repair of cracks, leaks, and other damage. The goal is to improve the durability and stability of the concrete and prevent further deterioration. This process helps extend the service life of the concrete structure and restore its integrity. For the injection we use liquid two-component epoxy resin to fill cracks and strengthen the concrete structure.

Concrete Injection with SLS Polymer Foam

Due to its many advantageous properties, we at SealteQ also make extensive use of SLS polymer foam. When the ground beneath highways, runways, or buildings is unstable, concrete structures can be damaged. To increase the soil’s bearing capacity, the soil layers are injected with SLS polymer foam—an ideal solution for soil stabilization and foundation repair. The foam is ultra-light, so it does not burden the subsoil or cause additional settlement. At the same time, it has high compressive strength—up to 700 tons/m²—meaning the ground can be subjected to heavy loads. Other properties of SLS polymer foam that contribute to strengthening concrete include:

- suitable for dry and wet conditions

- environmentally friendly

- free of PFAS compounds (poly- and perfluoroalkyl substances, a group of chemicals harmful to the environment and the human body)

- non-hazardous in contact with drinking water

- with insulating properties

Why waterproof concrete?

When cracks become visible in the concrete floor or structure, it is essential to take action immediately. Through concrete renovation and concrete repair, SealteQ’s specialists can assist you effectively. One method for repairing concrete is to inject it with a two-component epoxy resin. This method helps waterproof the concrete, repair cracks, and strengthen the structure.

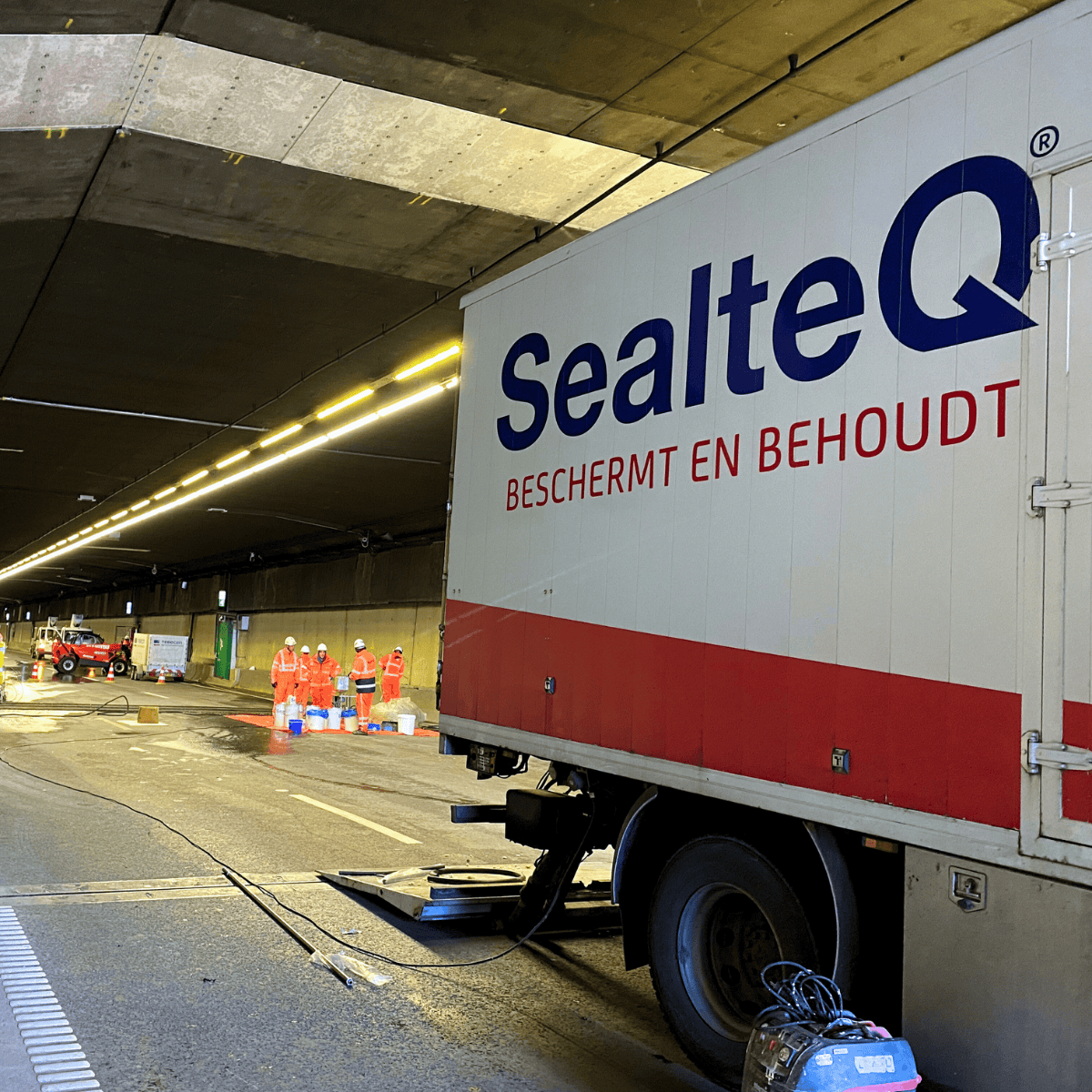

SealteQ is one of the pioneers in the Netherlands in the development and specialized execution of concrete injection. Using the techniques and materials outlined above, we provide strengthening and sustainable preservation of concrete in both large and small projects.

Concrete injection by SealteQ specialists

Are you noticing cracks developing in your concrete floor or looking for preventive solutions to waterproof concrete? At SealteQ, we work with innovative techniques that we have continuously developed over the past decades. This has improved speed and reduced costs. SealteQ has