Concrete impregnation is an effective technique that helps extend the lifespan and durability of concrete structures. The process protects concrete against harmful external influences such as moisture, chemicals, and wear. Read more in this article about the concrete impregnation process and its benefits for strengthening buildings and properties.

Concrete Impregnation: how Does it Work?

How does concrete impregnation work?

Concrete impregnation is a treatment where a protective liquid is applied to the concrete surface. This liquid penetrates deeply into the concrete and creates an invisible barrier that repels water, chemicals, and other harmful substances. This process differs from other treatments, where concrete coating and sealers form the protective layer on the surface.

The technique is applied in the following situations, among others:

- In commercial construction, for protecting parking garages against oil, fuel, and wear from vehicles.

- In infrastructure for protecting bridges and viaducts against corrosion and weather influences.

- For private homes and commercial buildings where aesthetics and protection of structural elements are improved.

Impregnation in 3 Phases

The impregnation of concrete involves several phases that must be carefully executed to achieve optimal results. These phases typically look as follows:

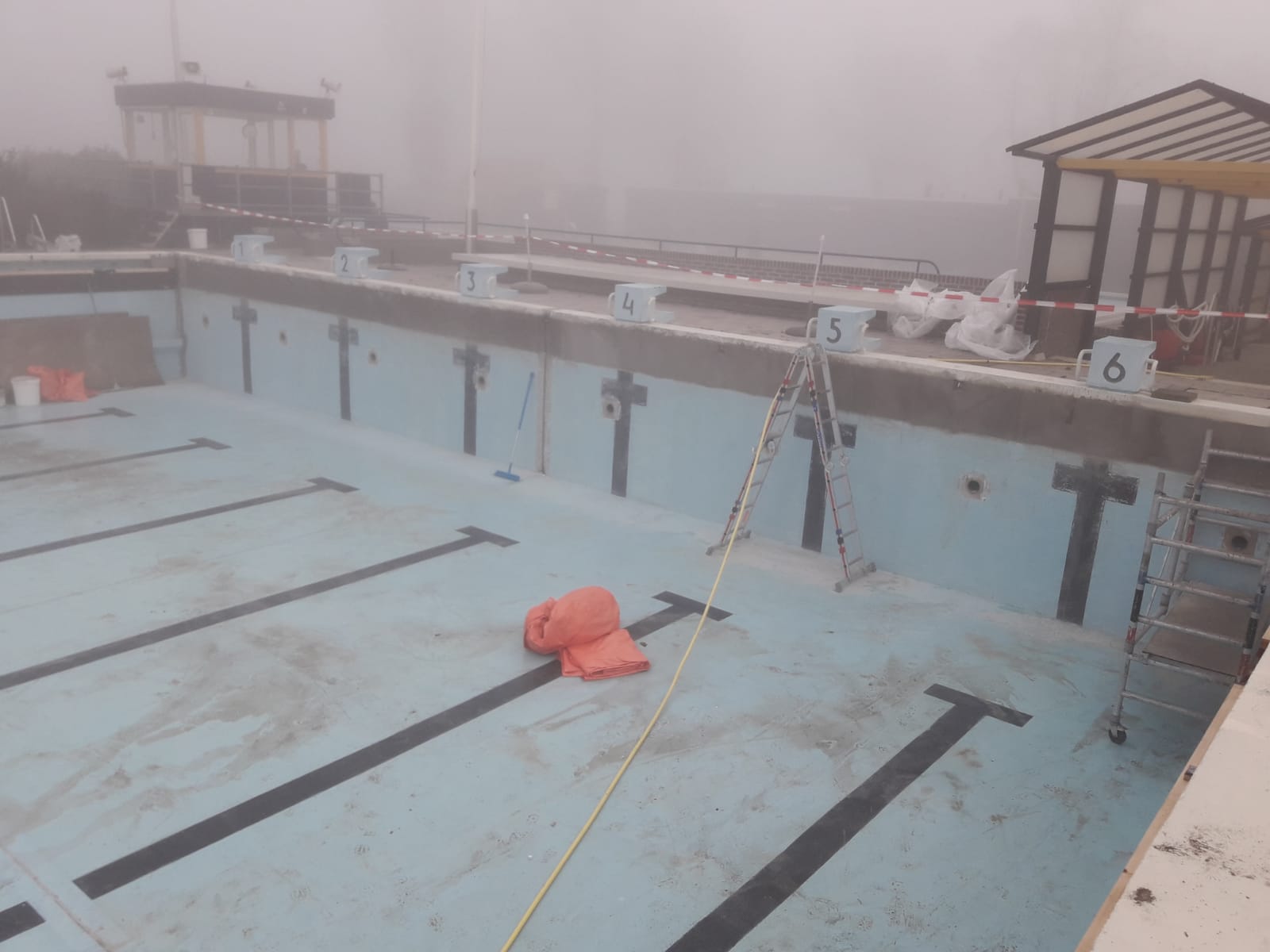

- Surface preparation: the concrete surface must be thoroughly cleaned to remove dirt, dust, and any old coatings. This allows the impregnating agent to penetrate effectively.

- Application of the impregnating agent: the impregnating agent is sprayed or rolled evenly onto the surface. The liquid penetrates the concrete and forms a protective layer inside the material.

- Curing and post-treatment: after application, the impregnating agent must be given time to fully penetrate and cure. This depends on the product used and the ambient temperature.

The chemical action of impregnating agents is based on a reaction with the porous structure of concrete, creating a hydrophobic effect that repels liquids.

Benefits of concrete impregnation

Concrete impregnation is typically done as part of concrete renovation and concrete repair. The main goal is to strengthen the existing structure and make it safer for users and passers-by. This technique offers numerous benefits that contribute to the durability and aesthetics of concrete structures:

- Extended lifespan: by protecting the concrete against moisture and chemicals, structural integrity is maintained and lifespan is extended.

- Protection against wear: impregnated concrete is more resistant to physical wear. This is especially important in heavily loaded environments such as parking garages and industrial floors.

- Improved aesthetics: the surface stays clean and stain-free longer, contributing to a well-maintained appearance.

- Resistance to freeze-thaw cycles: the hydrophobic properties protect the concrete against damage from freezing and thawing, preventing cracks and fissures.

Have your concrete impregnated by SealteQ specialists

For concrete impregnation and strengthening concrete structures, SealteQ offers the right expertise and proficiency as a reliable partner. We exclusively use high-quality impregnating agents that ensure durable and effective results. Through constant focus on innovation and maintenance of recognized

Frequently Asked Questions (FAQ)

- What is the difference between impregnating and coating concrete?

Impregnation penetrates deeply into the concrete and protects from within, while coating provides a protective layer on the surface.

- How long does the impregnation process take?

The duration of the process depends on the project scope, but it can typically be completed in a few days, including curing time.

- Why choose SealteQ for concrete impregnation?

SealteQ offers expertise, high-quality materials, and customer-focused service, ensuring you receive durable and effective results.