At SealteQ we apply various coating systems, tailored to the application, environmental factors and project requirements. We always work based on applicable standards, such as NEN-EN-ISO 12944, and ensure customized solutions that align with your project objectives.

Steel Preservation

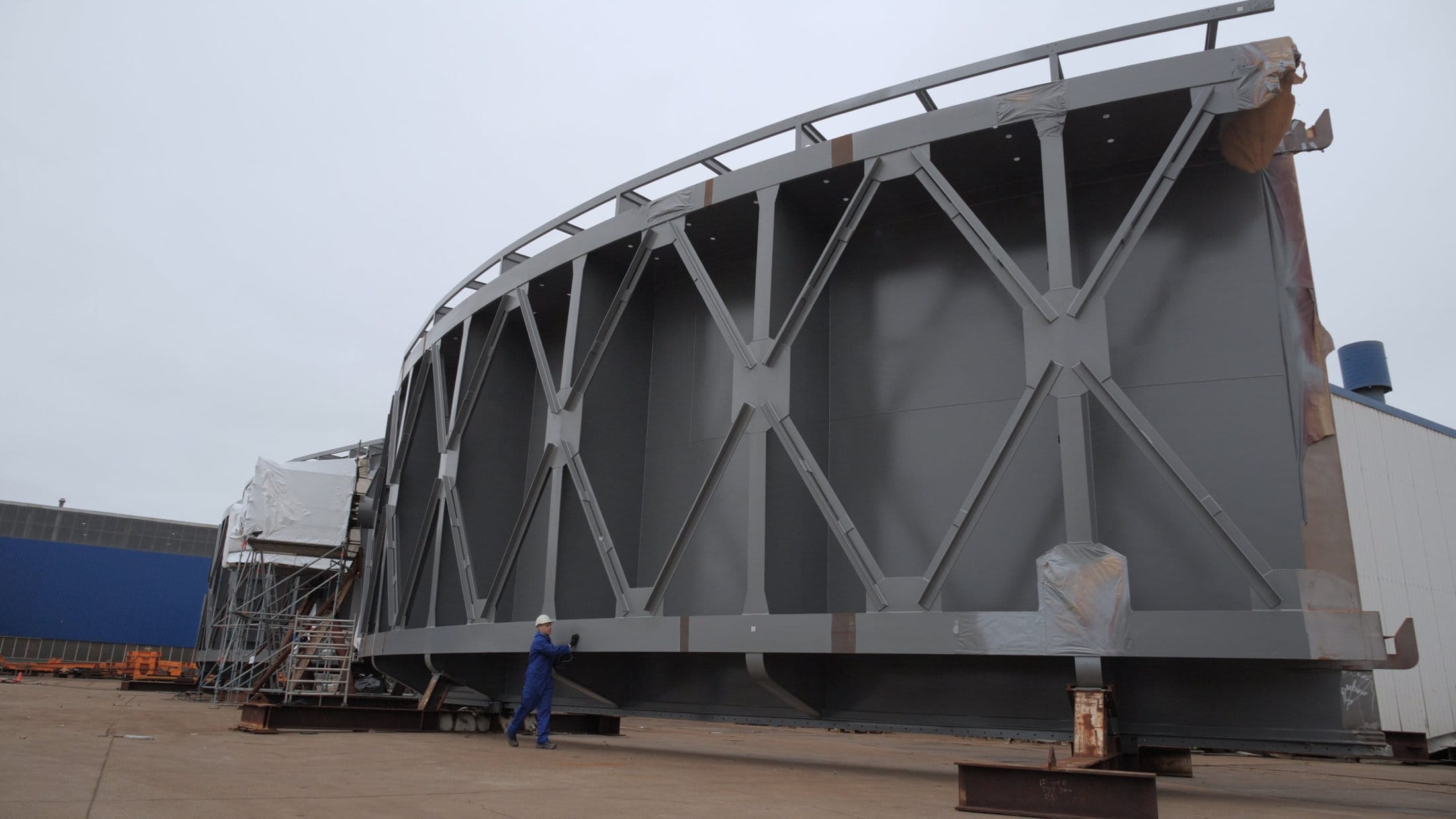

Steel coating is part of our steel conservation specialty. Steel conservation is intended to protect steel and preserve it as long as possible. Through steel coating, among other things, the surface is sealed from external influences. This keeps the structure safe, stable and aesthetically in good condition, with lower maintenance costs in the long term.

Thanks to our mobile equipment, we can conserve steel at any location in the Netherlands. Our mobile conservation units are equipped with:

- Mobile blasting and spraying equipment

- Metallizing installations (including Thermal Sprayed Aluminium)

- Extraction and filter units (including dust reduction and ventilation)

- Power generators

- Lighting and communication equipment

This makes steel preservation possible in operational environments such as hospitals or factories, without prolonged downtime or disruption of processes.

For projects that benefit from controlled conditions, we have two fully equipped conservation halls in Bergum and Bergharen. Here we perform surface treatment, metallizing and coating with maximum control over quality, layer thickness and adhesion. Our halls are suitable for large steel structures and feature advanced spraying and lifting installations.

Fire resistant coating

Making steel fire-resistant is mandatory in many buildings and installations. SealteQ is a specialist in applying fire-resistant coatings to steel structures according to requirements for 30, 60, 90 or 120 minutes fire resistance.

Our approach is as follows:

- Application of certified fire-resistant systems

- Application of multiple layers with controlled coating thickness

- Continuous measurement and inspection during application

- Final certification upon approval

These coatings are indispensable for buildings where structural integrity during fire must be guaranteed, such as parking garages, healthcare facilities or public buildings.

Specialized Applications

Depending on the situation, we also offer:

- Coatings for applications with high chemical resistance.

- Systems suitable for humid or sterile environments (such as in the medical sector).

- Recoating of existing systems, provided the substrate and adhesion are suitable.

- Combination solutions with, for example, thermal galvanizing of steel for extra protection.