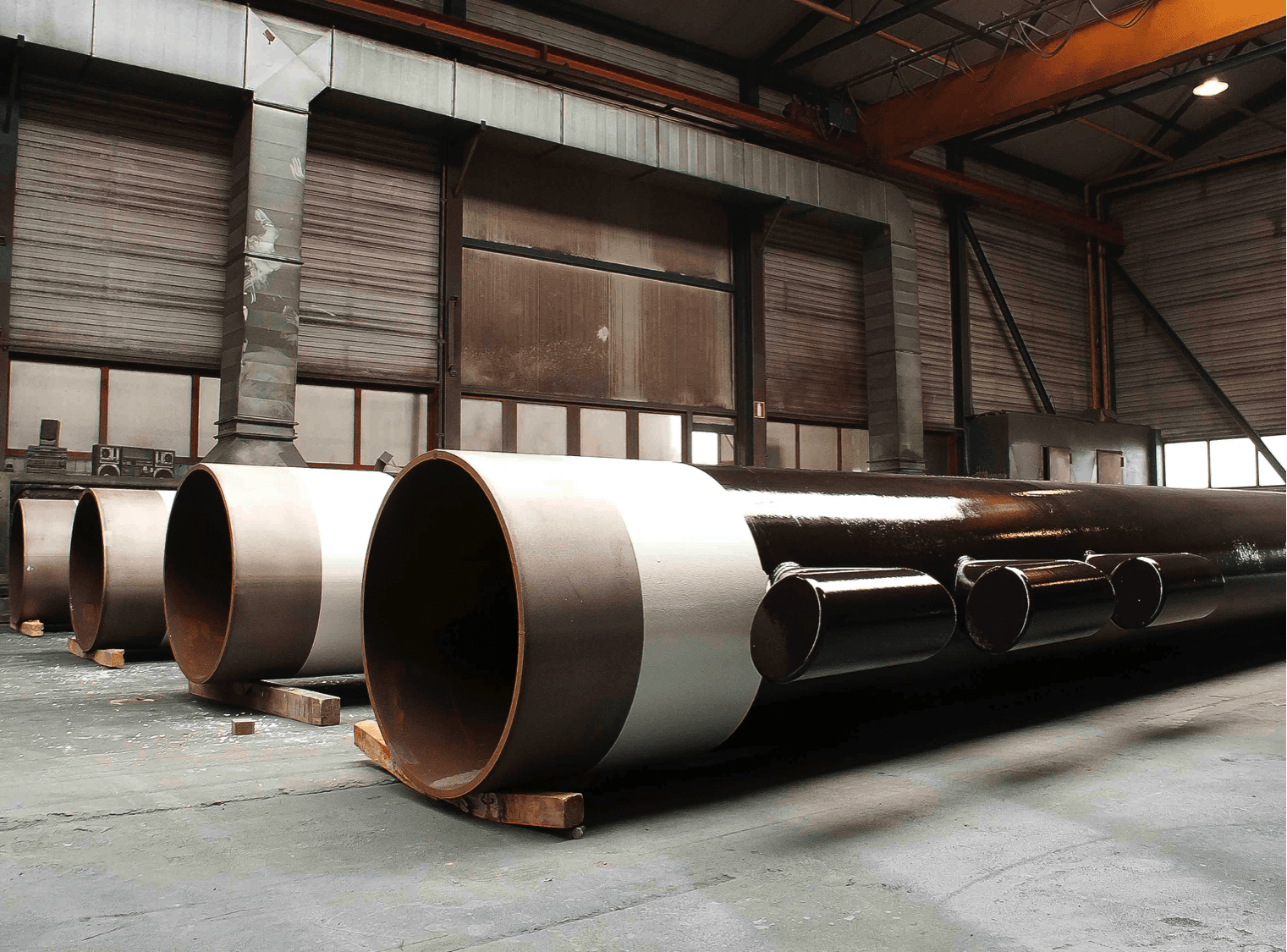

At two locations in the Netherlands (Bergharen and Bergum), we have modern, well-equipped conservation halls to perform blasting and coating work for steel completely in-house.

Steel preservation cabin

The locations (Bergharen and Bergum) feature:

- 5 large spray halls;

- spray booth (35 m x 4.5 m x 4.0 m);

- blasting machine (1000 x 2500 x 2500);

- blasting booths for steel, stainless steel and aluminum;

- overhead cranes;

- overhead conveyor system;

- modern spray equipment.

Disciplines:

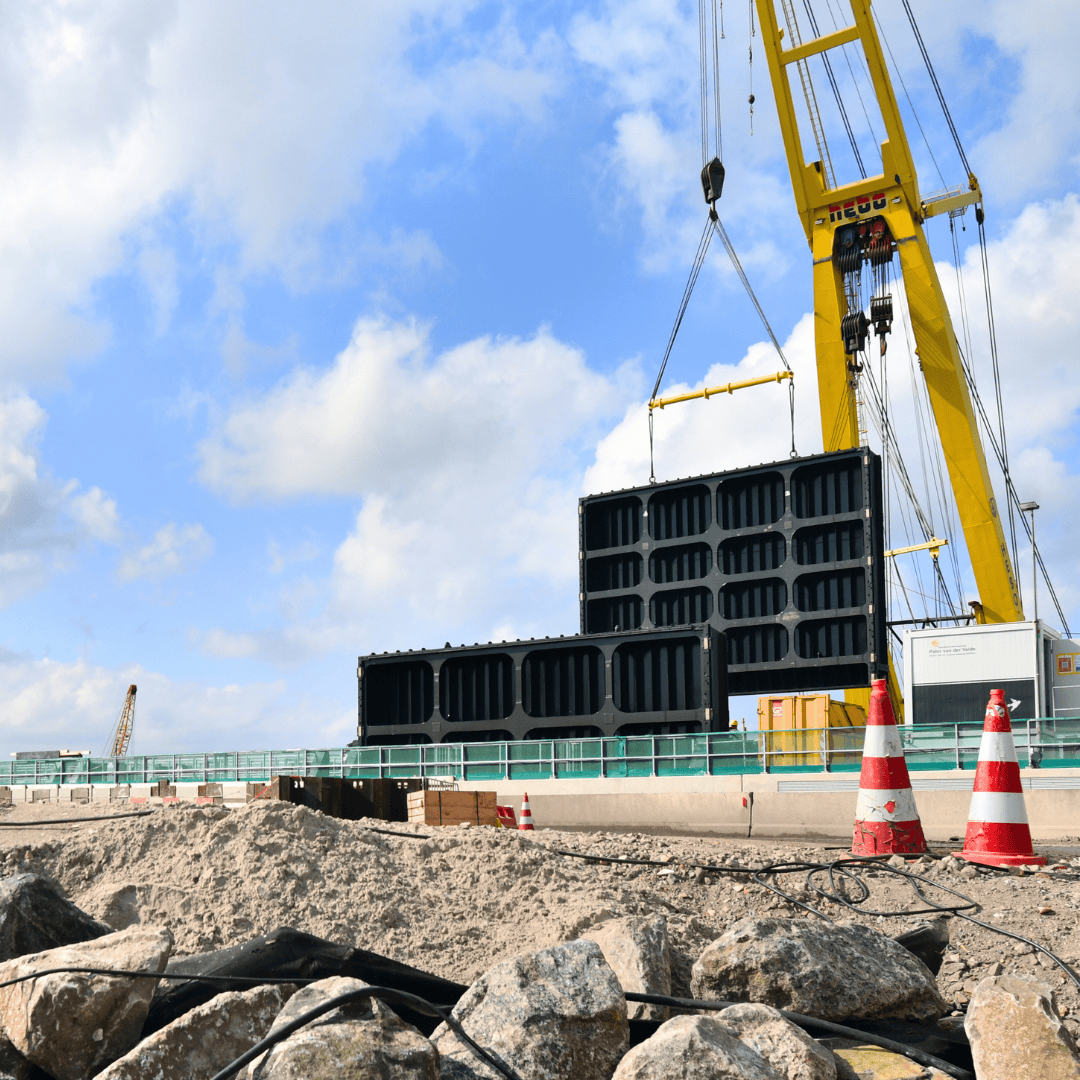

- blasting (with steel or corundum);

- aluminizing (TSA); We metallize steel structures by applying a thermally sprayed aluminum coating to a blasted surface. We call this conservation layer a TSA coating. TSA stands for Thermal Sprayed Aluminum. TSA is an active protective self-repairing spray coating that protects against corrosion. TSA can be used both above ground and underground. Compared to conventional paint systems, Thermal Spray Aluminum provides a much longer service life (minimum 30 years). This means lower maintenance costs in the long term.

- application of coating systems (single-layer to multi-layer systems, fire-resistant coatings, fiberglass coatings, etc.);

- quality registrations;

- inspections by NACE certified professionals;

- warranty certificates;

- consulting.