When the ground beneath, for example, railways, highways, civil engineering structures, and runways is unstable, settlements and damage to these constructions can occur. If the particle size of the soil layers beneath these structures is suitable, our SLS resins can be used to stabilize the subsoils with injection techniques. This increases the soil's bearing capacity, allowing the structure to be stabilized afterwards.

Ground stabilization

Identification of unstable soil

Identification of unstable soil is a crucial step in the ground stabilization process to timely detect and address potential risks and problems. There are various indicators and methods that help in identifying unstable soil:

- Visual inspection: a visual inspection of the site can often provide the first indications of potential problems. Look for signs of subsidence, cracks in buildings or roads, and visible changes in the terrain such as cracks in the ground.

- Geotechnical investigations: geotechnical investigations, such as soundings and borings, can provide detailed information about the composition and stability of the soil layers. Analysis of soil samples can help identify weak or unstable soil.

- Use of instrumentation: instruments such as soil moisture meters, inclinometers, and ground penetrating radar can be used to measure changes in ground conditions and detect potential signs of instability.

- Historical data: studying historical data, such as previous soil reports, geotechnical studies, and information on local geological features, can provide valuable insights into soil stability.

Ground Stabilization with SLS Polymer Foam and SLS-soil

SLS polymer resins are used for ground stabilization, where the bearing capacity of the soil is increased by injecting the non-load-bearing soil layers. This method is also applied for floor lifting in various industrial environments.

Properties of SLS Polymer Foam

SLS polymer foam is remarkably lightweight, with a density of only 52 kg/m³, which is approximately 30 times lighter than sand. This minimizes the load on the subsoil, preventing new settlements. It also has a high compressive strength, up to 700 tons/m², making it suitable for various applications.

Sustainability and Environmental Impact

SLS polymer foam is environmentally friendly and contains no harmful PFAS compounds. It is approved for contact with drinking water and minimizes environmental disruption. Due to its low weight and insulating effect, it contributes to a sustainable ground stabilization solution.

Applications

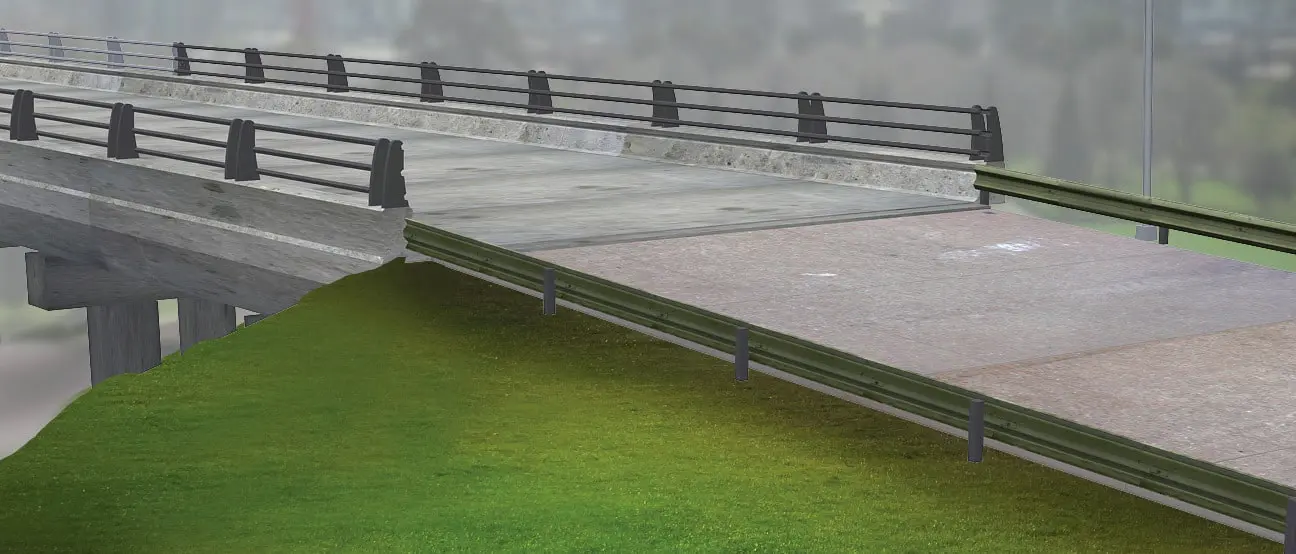

The two-component SLS polymer foam is designed for use in dry and wet conditions. SLS offers various SLS-soil products that can also stabilize much deeper soil layers. Based on sounding data, the particle size per soil layer is determined and classified. Subsequently, the appropriate SLS-soil product for each layer depth is determined. SLS polymer resins can be applied to:

- highways;

- railways;

- approach slabs;

- runways;

- sinkhole remediation;

- access roads;

- unstable ground.

After ground stabilization, concrete repair can be a logical next step, especially if the ground stabilization was performed to increase the bearing capacity of the subsoil for concrete structures. Concrete repair involves restoring damaged or deteriorated concrete surfaces to reinstate the structural integrity, durability, and aesthetics of the construction.

About SealteQ

SealteQ values quality and craftsmanship. That is why all our operating companies are certified according to an integrated quality system. Our activities meet the highest standards through our obtained certificates.

As a member of the Association of Certified Concrete Repair Companies (VBR), we are committed to sustainability, safety, and corporate social responsibility.

SealteQ recognizes its social role and strives for a positive contribution. Therefore, we use the United Nations’ Sustainable Development Goals (SDGs) as a guideline for our CSR policy. Our focus is on three SDGs, through which we actively contribute to a better world by 2030.

Curious about what we can do for you? Please contact us.