The lighthouse on Vlieland has been delivered by SealteQ to Rijkswaterstaat. A renovation full of challenges and setbacks. The work that started in September 2018 should have been completed in October 2018. However, research revealed that the existing coating on the lighthouse contained Chromium-6. This caused the work to be halted and further investigation had to be conducted to exclude health risks. Add the storm season to the mix and the work could only be resumed in May 2019. Two months later, in July, the lighthouse on Vlieland was fully renovated and reopened to tourists.

Renovation of Vlieland lighthouse completed

Chrome 6

Recently, Chromium-6 has been frequently in the news in a negative context. It appears that paint containing Chromium-6 has been applied more often than initially thought. For example, last year in September (September 5, 2018), it was announced in a letter to the House of Representatives that coatings containing Chromium-6 have been used in multiple Dutch government buildings. Research shows that Chromium-6 also occurs on other real estate, because it was widely used in rust-resistant coatings in the past.

Removal of the Coating

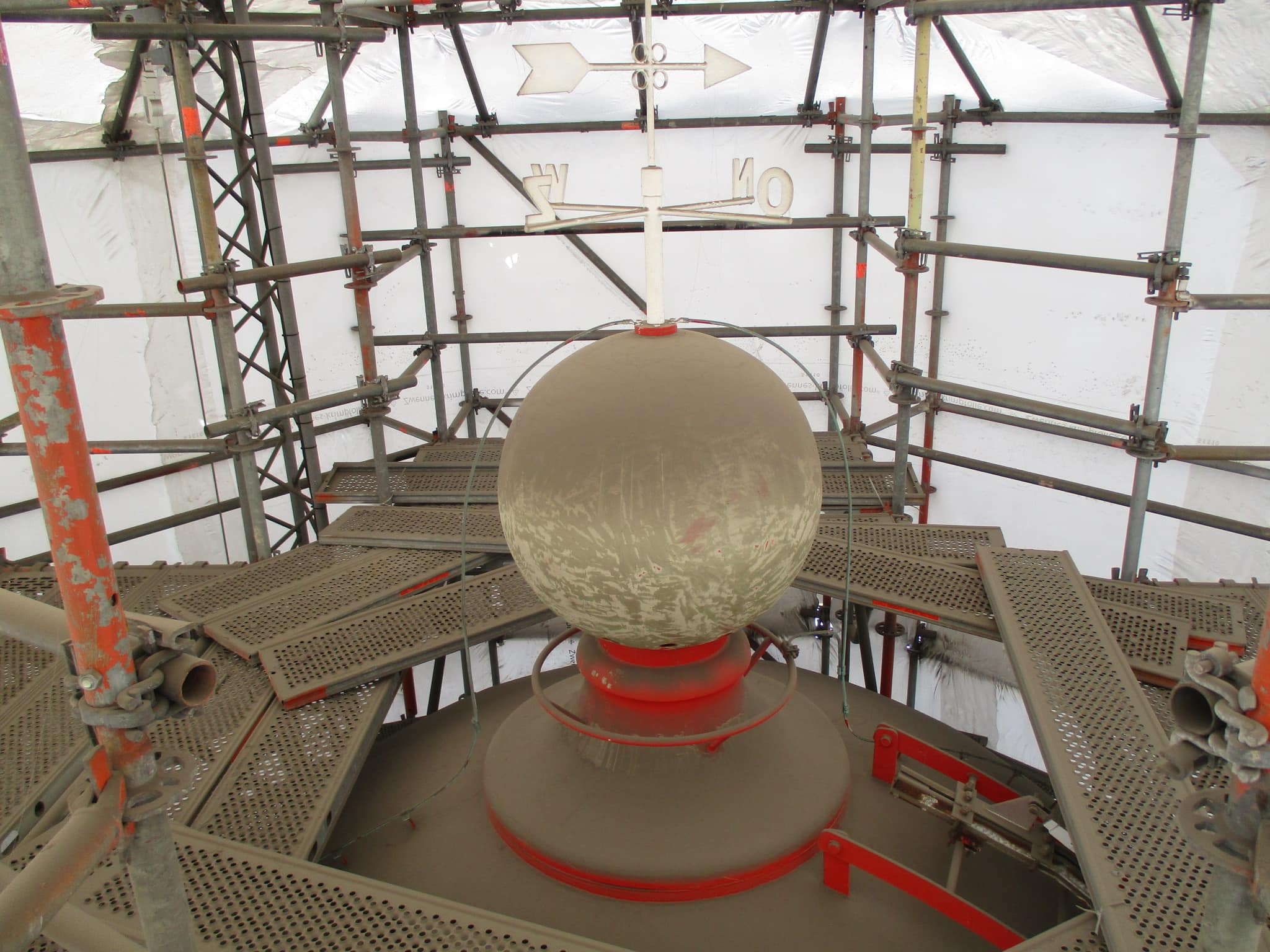

The existing coating in which Chromium-6 was found has been removed by induction. Induction is a process where the steel is briefly heated, causing the coating to lose its adhesion. A major advantage of this process is that no dust is released. This makes it an extremely suitable system for removing Chromium-6. Unfortunately, induction could not be applied everywhere on the lighthouse to remove the coating. On the detailed surface of the lighthouse, the coating was removed by sponge blasting. In sponge blasting, the grit particle is enclosed by a PE sponge. During blasting, the blast dust is absorbed by the sponge, resulting in a significant dust reduction. When carrying out all these activities, we took the necessary safety measures.

Application of New Coating System

Before starting the conservation work, the lighthouse was blasted to a cleanliness grade of Sa 2½ in accordance with ISO 8501-1/2. Subsequently, the lighthouse was provided with a four-layer coating system consisting of multiple colors. Corners, edges, bolts and nuts were first pre-coated to ensure sufficient coverage. After this, the lighthouse was further provided with a rust-resistant coating using an airless pump. The bottom three meters of the lighthouse is provided with a special anti-graffiti coating. Through the application of the four-layer coating system, the service life of the lighthouse has been significantly extended.

Other Work

After the lighthouse was provided with the new coating system, the natural stone base on which the lighthouse stands was provided with a three-layer coating system using brush and roller application. Subsequently, a number of components of the lighthouse post were replaced. For example, all deteriorated and poorly sealing sealant joints, the bituminous roof covering including roof boarding and the fencing were replaced. All doors were also re-hung and made to close properly.

Thanks to the life-extending work by SealteQ, the lighthouse on Vlieland is once again protected against corrosion for years to come. Are you curious about the possibilities that SealteQ can offer you regarding the removal of Chromium-6 or the conservation of steel on location? Please feel free to contact one of our offices.