SealteQ, commissioned by the Municipality of Arnhem, started renovating the Arnhem Central car park at the beginning of this month. The work will take approximately 40 weeks, divided into three phases. During this period, the current screed will be removed. A new screed will be applied, and finally, a coating system will be applied. The aforementioned work will significantly extend the lifespan of the car park.

Renovation of Arnhem central parking garage

Removal of the Current Screed

The first phase of the work consists of removing all obstacles on the floor. The obstacles mainly consist of speed bumps and warning posts on which traffic signs with the maximum permitted speed are mounted. Once all obstacles have been removed, the removal of the existing screed can begin. This work consists of demolition and blasting.

Application of New Screed and Coating System

Once all work relating to the removal of the current floor has been completed, a new armored screed will be applied. The armored screed will also be blasted to give the surface the correct roughness so that the coating system can bond properly with the substrate. Before the subsequent steps can be carried out, the substrate must have a minimum tensile strength of 1½ N/mm². This is necessary to then apply a coating system. The coating system consists of several layers: a primer layer, a scratch coat, a flexible membrane, a top coat, and finally the markings and pictograms.

Update may 24, 2019

The first phase of the renovation of the Arnhem Central car park was completed last week. Phase 1 is the first of a total of three phases into which the renovation work is divided. The work started with the removal of the obstacles. In this case, the obstacles are speed bumps and warning posts. After this, the screed of parking level 4c was demolished and removed. After the screed was demolished and removed, the underlying floor was dust-free blasted and vacuumed. The floor parts that were not accessible to the dust-free blasting unit were pre-treated manually with a diamond grinder with extraction.

Application of the Coating System

This pre-treatment ensures that the existing substrate is free of dirt, grease and dust. This is necessary because a sufficiently rough and load-bearing substrate must be created for the new screed and coating system to be applied. After the pre-treatment, some tensile strength measurements were carried out. The substrate must have a minimum tensile strength of 1½ N/mm². Only after approval of the tensile strength of the substrate was the application of the armored screed started. After the armored screed was applied, the floor was blasted dust-free. The substrate was then provided with a primer, scratch coat, flexible membrane and finally the sealing layer. After the entire coating system has hardened, the parking spaces, markings and pictograms are applied.

Phase 2

The second phase of the renovation of the Arnhem Central car park relates to levels 4a and 4b. An extra ventilation/extraction unit has been placed for phase two. In phase two, the work also starts with the removal of the obstacles. Subsequently, the subsequent steps of the work will proceed in the same way as in the first phase of the renovation work.

View the next project

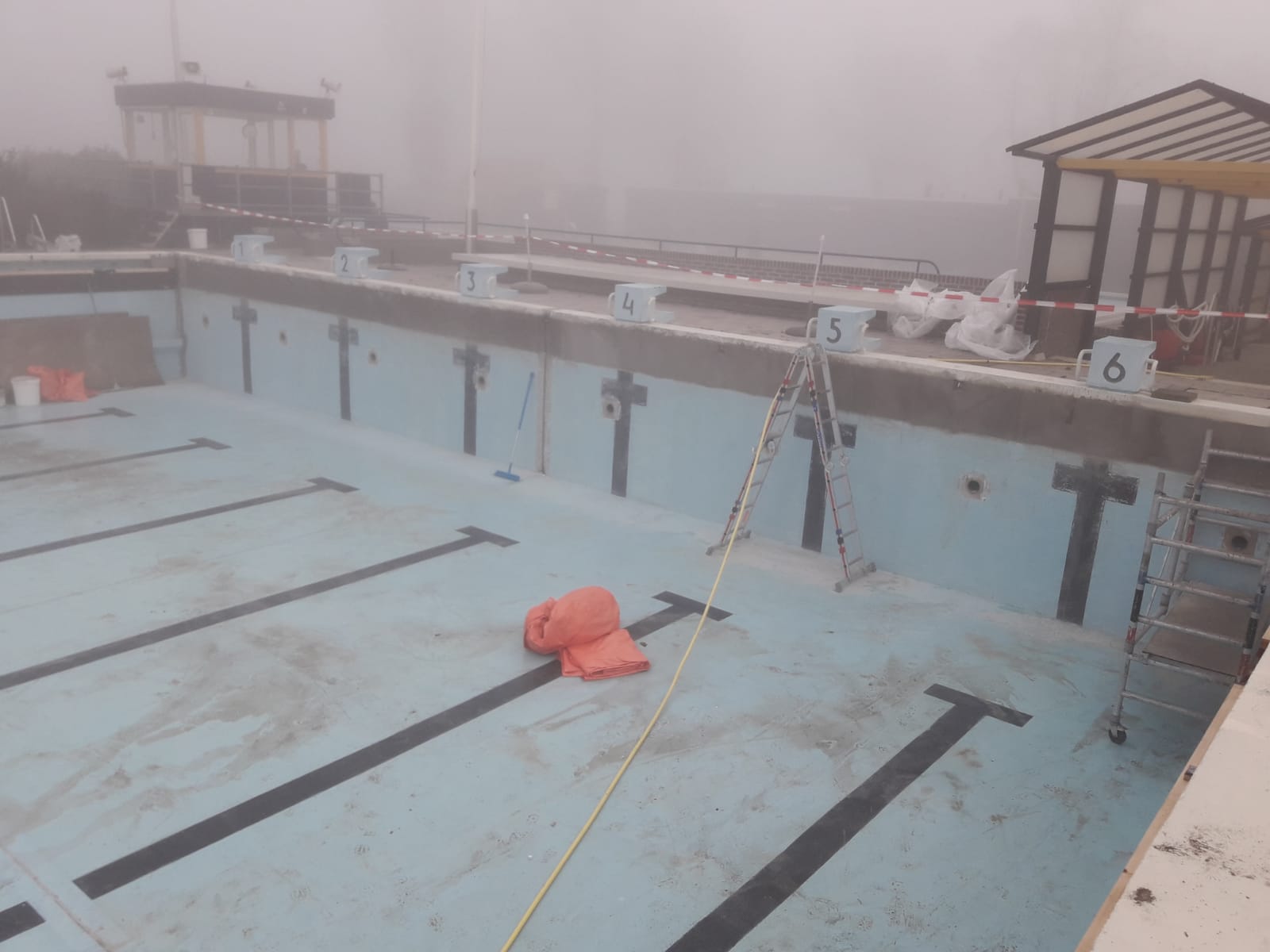

Replacing the wall tiling of swimming pool the Delte

Last week, SealteQ commenced work on the swimming pool De Delte in Gorredijk. The work carried out by SealteQ will involve the deep pool. The wall tiles and the overflow gutter of the pool will be demolished and then replaced.