The specialists from SealteQ Heerenveen are currently engaged in an extensive renovation project covering 7,700 m² in the Zaailand parking garage in Leeuwarden. Zaailand is the largest parking garage in the city and is strategically located in the center, which underscores the infrastructural importance of this project.

Coating parking garage Leeuwarden

To minimize inconvenience for users, the project is being executed in phases. In each phase, a different part of the parking garage is blasted and recoated. Phase one commenced immediately after the construction holiday and was completed within five weeks. Phase two has now also been completed. The plan is to deliver phase three by early 2025.

The work includes dust-free blasting of the floors, pre-treatment of the substrate, and application of a primer screed layer. Subsequently, a flexible membrane layer is applied. The driving lanes are sprinkled with Testra 01-05 mm to create good wear resistance and anti-slip properties. After drying, excess sand is removed. The finishing is completed with a high-quality finish and the necessary signage.

To provide anti-slip properties to the parking spaces as well, these are finished with a coating containing glass beads. This system was developed in collaboration with Parkeergarages Leeuwarden. A test section was installed a year and a half ago, which demonstrated that the developed system meets the requirements for anti-slip properties, wear resistance, and cleanability.

SealteQ is confident that this approach will not only ensure a durable and safe parking garage but also an efficient execution of the work. We look forward to the progress of this project and the positive impact it will have on parking facilities in Leeuwarden.

Related markets

View the next project

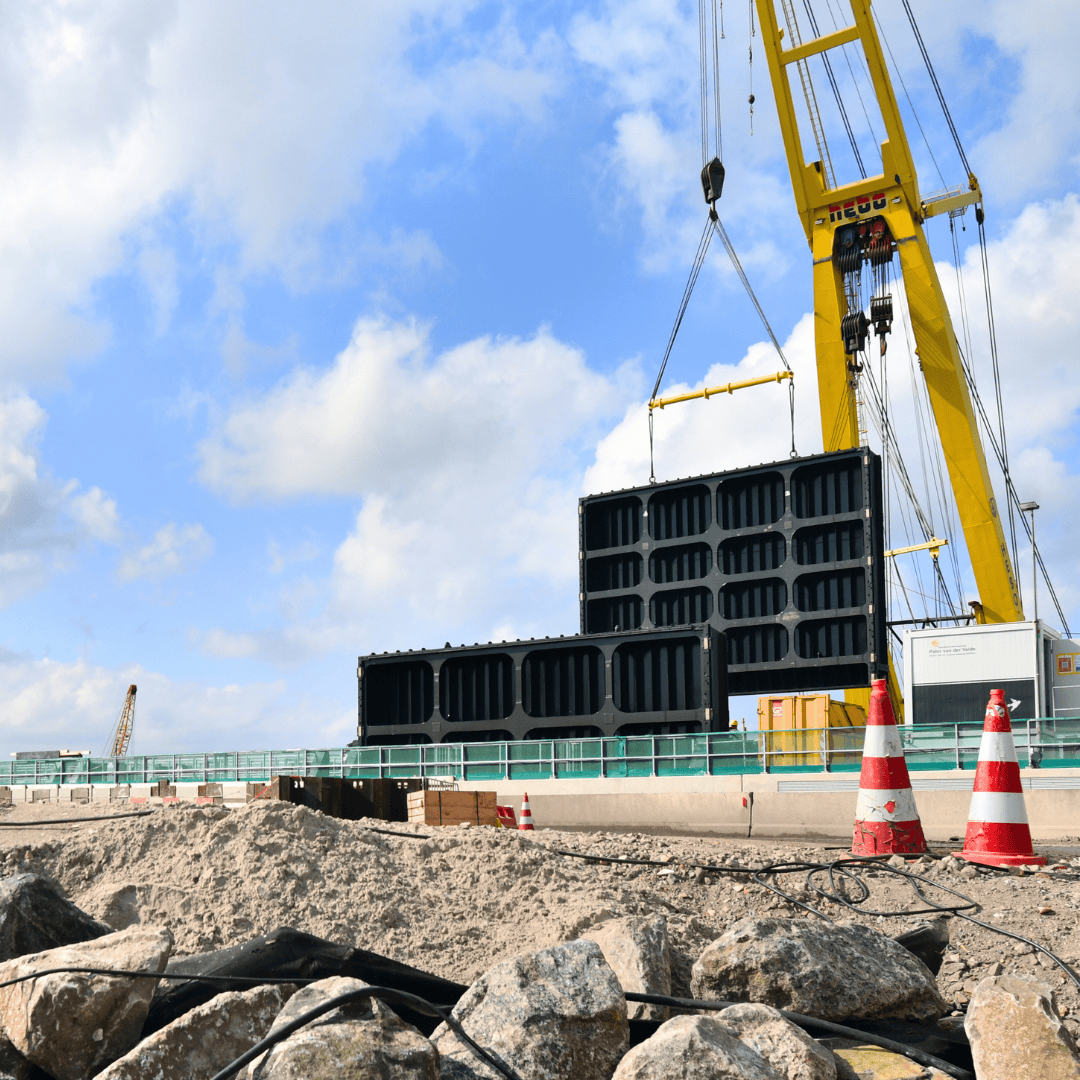

Conservation of duckweed gates and sluice gates Afsluitdijk

The specialists from the blasting cabin in Bergum, commissioned by Solidd Steel Structures, have provided the conservation of weed racks and sluice gates for the Afsluitdijk. SealteQ is proud to contribute to the impressive and large-scale project at the Afsluitdijk.